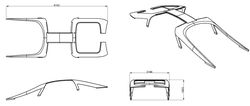

The piece is problematic due to its complex design, size, and curvy, sinuous shape. It is a single custom piece that requires several stages of processing, therefore expensive and not scalable.

| Details of print element | |

|---|---|

| Lenght | 815 cm |

| Width | 320 cm |

| Tickness | 2 cm |

| Weight | 60 Kg |

| Print time | 80 hours |

The piece is problematic due to its complex design, size, and curvy, sinuous shape. It is a single custom piece that requires several stages of processing, therefore expensive and not scalable.

Precision, accuracy, resistance. Easy to laminate, good adhesion of other materials, perfect execution of the forms to mount it on the existing structure of the boat. Cost competitive production compared to traditional process. Easy to carry and ship.

Optimization and printing of custom element divided into parts with integration of assembly system.

Stiffness is achieved through localised addition of patented isogrid system.

Perfectly matching shape of desired piece, 2 times faster than milling; simplified and faster working process, easier to handle thanks to the lightness of the element; reduced waste, increased sustainability of the process and minor impact on the environment; contained, optimised packaging with reduced volume and remarkable cut of costs of transport.